Finding the correct magnet material for your application can be tough due to the wide range of materials available and the extensive knowledge of each required to decide, at Magnet Expert we have vast experience working with high-performance magnets and are here to help.

With over 40 years of experience in the magnetic industry, we have seen a range of effective magnetic solutions through an array of industries using all magnetic materials, but the two most common are Alnico and Neodymium.

Neodymium or rare earth magnets are some of the strongest permanent magnets available and offer higher performance than Alnico and ferrite, however, Alnico remains one of the most commonly used materials in several applications.

But what are neodymium and alnico magnets and the different benefits they offer?

What are Neodymium magnets?

Neodymium magnets are the strongest permanent magnets commercially available; they provide unparalleled levels of magnetism and resistance to demagnetisation when compared to alnico, ferrite, and even samarium-cobalt magnets.

Since the creation of the first neodymium magnet, they have cemented their position as the most popular magnets in endless applications because of their super-strength, resistance to demagnetisation, and their availability in numerous sizes and shapes.

Neodymium magnets are hard and prone to corrosion, making them brittle, but at Magnet Expert, we add the element dysprosium into the mix and coat, unless requested not to.

What are Alnico magnets?

While Alnico magnets have been largely replaced by stronger rare-earth magnets for some applications, Alnico magnets are still commonly used in the manufacturing of sensors, guitar pickups, relays, and high-temperature handling equipment.

Alnico has high magnetic strength and low resistance to being demagnetised and re-magnetised, which is why Alnico plays a critical part in all electro-permanent magnetic chucks and lifting magnets.

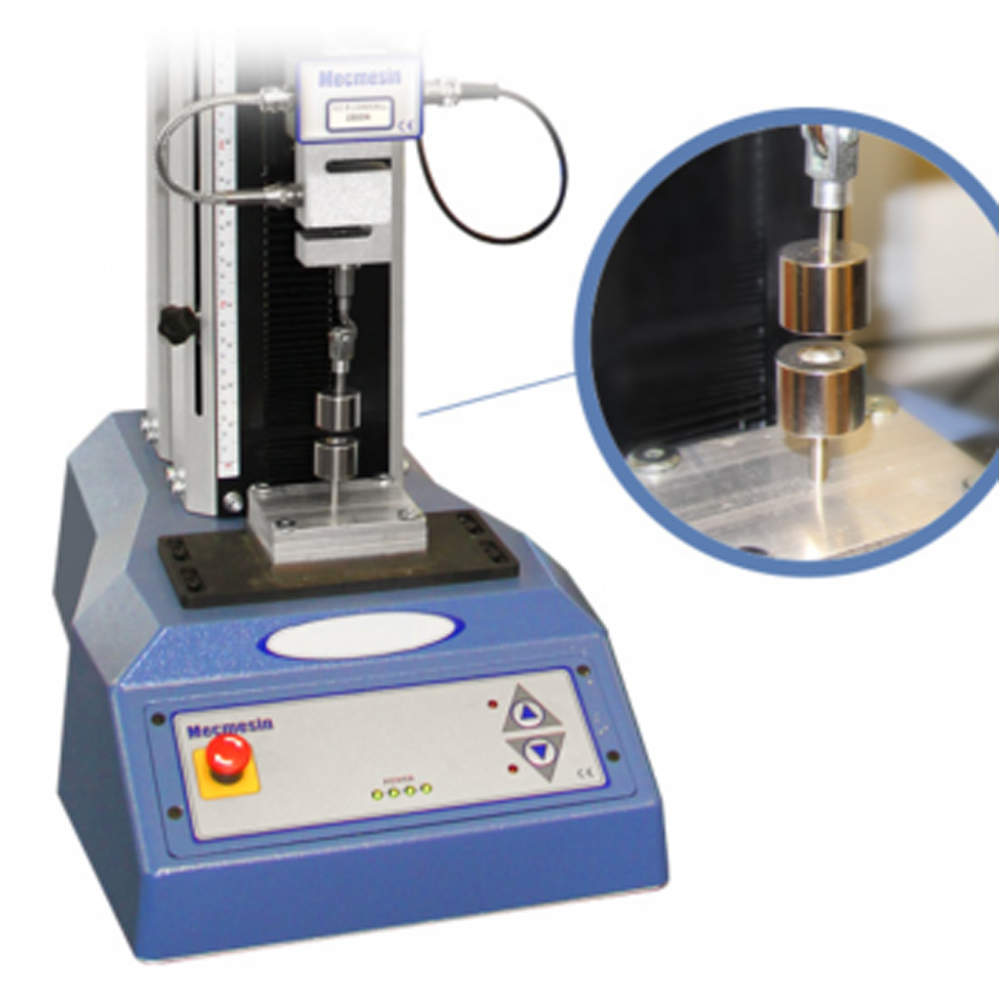

By wrapping coils of wire around alnico magnets, they can be easily magnetised and demagnetised by electricity flowing through the coils, meaning 100 tonnes per square meter clamping chucks can be switched on and off in 0.2 seconds because of Alnico magnets.

Which Magnet Material to Choose For Your Application

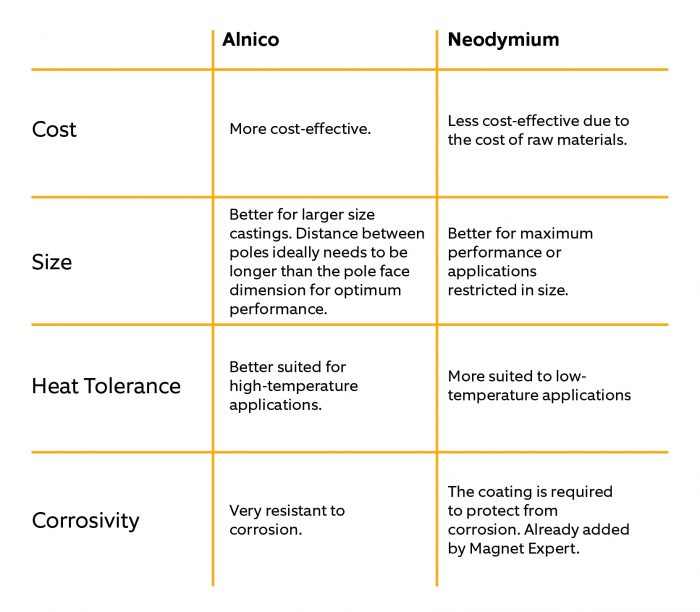

When considering what magnetic material between Neodymium and Alnico to use in your application, there are several key points to consider to decide which material would work best.

Here is a summary of key points when choosing between Alnico and Neodymium:

Unsure which magnet material to use for your industrial application?

Here at Magnet Expert, we welcome any enquiry about magnets and their applications, contact us today on 0845 519 4701 or please feel free to email us at sales@magnetexpert.com.