Welding is the process of joining two pieces using heat, pressure or both forming a join as the parts cool and solidify. However, securely holding metal workpieces in place during welding can be a challenging task, this is where magnetic welding clamps are essential.

Magnetic welding clamps are specially designed tools that use magnets to hold metal workpieces during welding, even when working with complex shapes and awkward angles.

Below we explain how magnetic welding clamps are used and their benefits.

How Magnetic Welding Clamps Work

Our magnetic welding clamps are made up of a ferrite magnet and a clamp. Ferrite magnets not only provide great strength but are extremely heat resistant and have a low production cost. The clamp is used to hold the workpiece in place, and the magnet attaches to the clamp, holding it securely against the metal workpiece.

The ferrite magnet creates a strong magnetic field to hold the workpiece in place, allowing the welder to focus their attention on the welding process, without the fear of the workpiece moving or shifting.

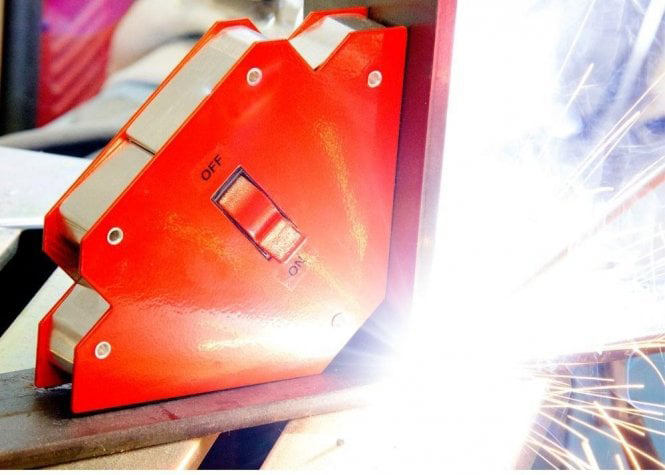

Some magnetic welding clamps are attached with a mechanical switch allowing them to be turned off, freely, and accurately positioned as there is no external magnetism, before being turned on to clamp the magnet in place.

An added benefit of the switching mechanism is the magnet can be quickly and easily cleaned, for when it is switched off any metal swarf can simply be wiped off.

Benefits of Magnetic Welding Clamps

Secure Hold

The main benefit of a magnetic welding clamp is its ability to securely hold metal workpieces in place throughout the welding process. This is extremely useful when working with complex shapes and awkward angles, where traditional clamps cannot provide enough holding power.

Easy To Use

Another benefit of magnetic welding clamps is how easy they are to use. They can be fitted to a workpiece with ease and quickly adjusted as needed, making them ideal for numerous welding projects.

No Marks or Damage

Unlike traditional clamps, magnetic welding clamps do not leave any marks or damage on a workpiece, as they hold the workpiece without applying any pressure.

Extremely Versatile

Magnetic welding clamps are extremely versatile in comparison to traditional clamps, they can be used on a wide variety of metal surfaces such as curved and irregular surfaces, and can be used in different welding applications, including MIG, TIG, and Stick welding.

Safety Considerations

Magnetic welding clamps are safe to use, but it is important to take certain safety precautions.

The strong magnetic field can attract loose ferrous objects, such as nails, screws, or tools, which could become projectiles if they become loose during welding.

Welders should always wear appropriate personal protective equipment, including gloves and eye protection, and ensure that the work area is free of any metal objects that could be attracted to the magnetic field.