Steel mills across the country and all the world round rely on different magnetic solutions to improve the handling, clamping, and lifting of steel and other materials, as well as playing a key part in the removal of ferrous debris from fluids such as oils, water, coolants and wash solutions ensuring the quality and surface finish of the steel are not compromised by ferrous contamination.

With our expertise and knowledge of the steel industry, we are confident in our ability to provide the right product for the application, we are in frequent contact with steel mill operators and understand their changing needs.

Magnetic Chucks For The Steelworks Industry

Our magnetic chucks have been engineered, to give the customer an effective and instant holding force, that will consistently and safely clamp the material they are working on while providing clear access to five faces.

Benefits of Using a Magnetic Chucks

Improved Efficiency

During operation, chucks reduce the time between swapping ferrous pieces and, therefore, improve the efficiency of a working day.

Improved Safety & Accuracy

Permanent magnetic technology ensures no slippage, movement, or vibration helping increase accuracy.

Clear 5-Face Access

Once the ferrous material is placed on a magnetic chuck, users have clear access to 5 faces at any one time.

Easy Waste Removal

After completing the work on the ferrous material, it is easy to remove waste and reload the next item through the magnetic chuck’s instant on/off functionality.

Magnetic Filtration System For The Steelwork Industry

Magnetic filtration systems are widely used in processes such as steel rolling, cutting, surface treatment, sawing, wash systems, and threading.

Our magnetic filtration systems will remove high volumes of fine ferrous particles from fluids such as coolants, water, wash solutions, and oil, to ensure the quality and surface finish of the steel are not compromised by ferrous contamination.

The process of removing ferrous debris from fluids can save your business money over time by extending the lifespan of your processing equipment, and fluids, as well as reducing the hours required for cleaning.

Benefits of Magnetic Filtration Systems

Enhanced process productivity

Breakdowns, wear & machine downtime in processing lines are reduced.

Improved health & safety

With contaminant-free processing lines, bacterial growth is minimised.

Reduce consumable filter costs

Through our high-quality systems, there is no need to replace consumable media filters.

Environmentally friendly

Filter waste and fluid disposal is reduced allowing for ferrous waste to be recycled.

Increased product quality

With cleaner fluids in processing lines, product quality remains at the highest level.

Extended fluid & coolant life

Through filtering ferrous contaminants, costs are reduced and fluid disposal decreases.

Lifting and Handling Magnets For The Steelwork Industry

Magnetic lifting and handling systems use permanent, switchable magnetic technology that delivers lifting speed, accuracy, and efficiency whilst ensuring safety.

Ideal for use in warehouses and industrial settings our lifting and handling magnets have been tested to lift up to three times their safe working load.

With instant on and off operation applying magnetics to steel lifting and handling applications can improve your lift rate at no additional cost.

Benefits of Magnetic Lifting & Handling Magnets

Increased Efficiency

With instant on and off operation applying magnetics to steel lifting and handling applications can improve your lift rate at no additional cost.

Precise Lifting & Load Safety

Our devices provide a secure instant hold ensuring no-load slippage and accurate lift placement, meaning no risk of damaging the load.

No Running Costs

Our range of magnetic lifting and handling systems use permanent, switchable magnetic technology, meaning they do not require a power source to maintain the lift hold.

Maximise Storage

Magnetic lifters are ideal when floor space is limited. Magnetic lifting only requires access to a single face of the load.

Magnetic Tools Used Every Day In The Steelworks Industry

Here at Magnet Expert, we supply numerous tools used to increase the speed and efficiency in a steel-producing environment, simple to use products such as Magnetic Sweepers and Multi-Angle Welding Magnets are used daily throughout a working day.

Our versatile range of Neodymium and Ferrite sweepers is the perfect tool for sweeping areas to clear ferrous debris such as loose screws, nuts, bolts, and metal shavings, avoiding stress, injury, and the cost of replacing stock due to damage. Shop the range below.

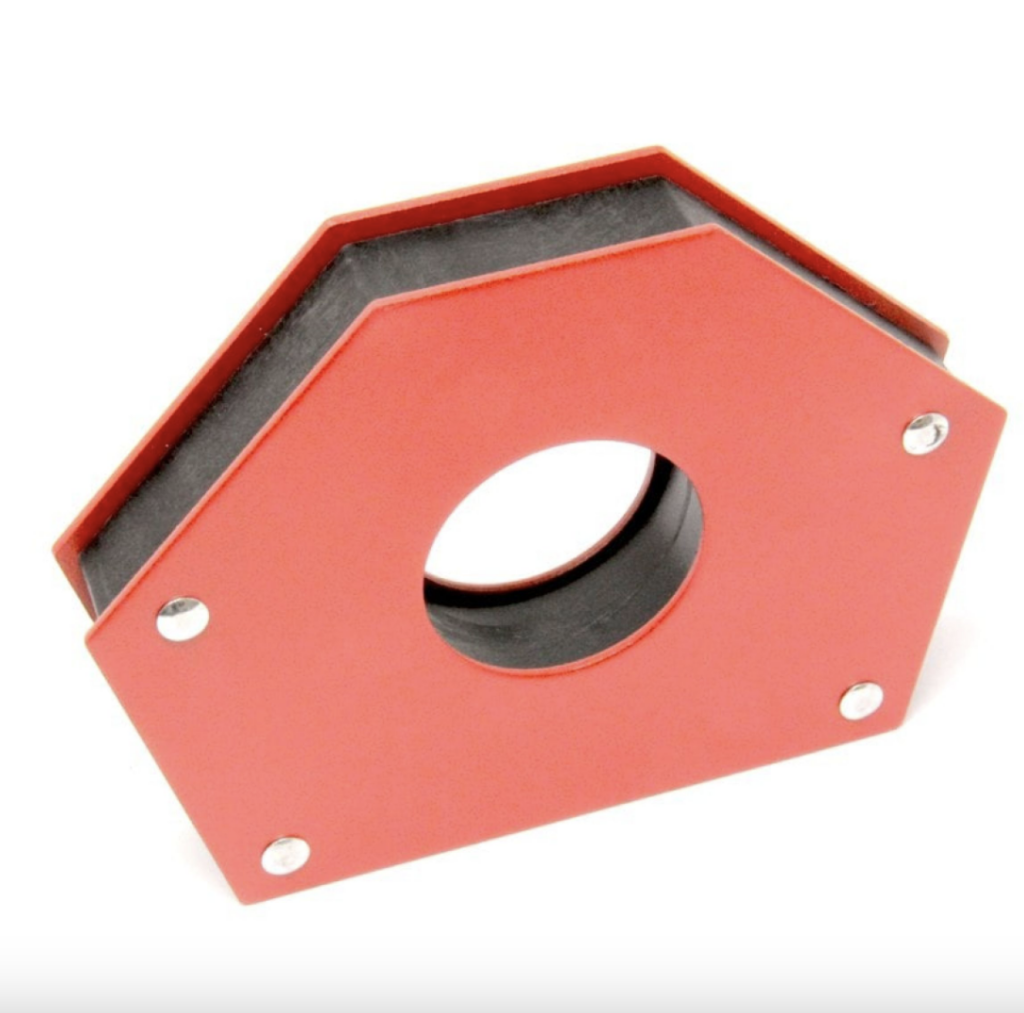

Multi-Angle Welding Magnets are designed for holding ferrous sheets and tubes in place while they are welded, these strong and compact magnetic clamps can be used for welding angles at 30°, 45°, 60°, 75°, and 90°. The convenient center hole provides secure and easy handling when in operation.

Do You Require Magnets For Your Steelwork Business?

Be sure to source your magnets from a reliable manufacturer and supplier and understand the magnetic materials used in them and their capacity.

Here at Magnet Expert, we welcome any inquiry about magnets and their applications. Contact us today at 0845 519 4701 or please feel free to email us at sales@magnetexpert.com.