In recent years, the use of magnetic filtration has become more prevalent than ever in a variety of industries, including aerospace, automotive, and food processing. Magnetic filtration is the process of using magnetic fields to separate magnetic particles from a liquid stream.

It is a cost-effective and efficient method of removing ferrous debris throughout industrial processes, and below we will explore how magnetic filtration is used to improve process and product quality in different industrial applications.

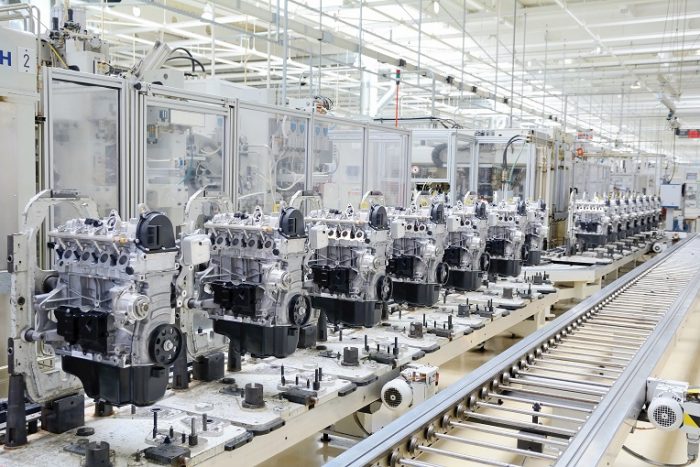

Automotive Industry

Magnetic filtration is used within the automotive industry to remove contaminants from oil, coolant, and fuel systems.

Commonly used in engine oil filtration magnetic filters remove metallic debris from the oil, helping increase the lifespan of engine components, reduce wear and tear, and improve the engine’s overall performance.

Magnetic filters are also often used in fuel systems to remove contaminants to prevent damage to the engine and a decrease in fuel efficiency. Finally, magnetic filters are used in coolant systems to remove metallic debris and prevent corrosion which can lead to engine overheating or failure.

Aerospace Industry

Within the aerospace industry, magnetic filtration is often used to remove ferrous debris from hydraulic systems, fuel systems, and lubrication systems.

Magnetic filters are used to remove ferrous particles from hydraulic fluid, helping prevent damage to hydraulic components and system failure. In fuel systems, magnetic filtration is used to prevent engine damage and a decrease in fuel efficiency.

Magnetic filtration systems are also used in lubrication systems to remove metallic debris and prevent wear and tear on engine components.

Food Processing Industry

In the food processing industry, magnetic filtration is used to remove metal particles from food products, helping to ensure the quality and safety of food products and preventing contamination.

Most commonly magnetic filters are used to remove ferrous particles from food products, such as sugar, flour, and cocoa powder. Magnetic filtration is also used in the production of beverages, such as beer and wine, to remove metallic debris and prevent spoilage.